What are the Advantages of Hot-Selling Vertical Wire Rock Wool Composite Board Products?

I. Introduction

In the ever-evolving world of construction and insulation materials, vertical wire rock wool composite boards have emerged as a hot-selling product, gaining traction across various industries. These innovative boards combine the natural properties of rock wool with the structural reinforcement of vertical wires, resulting in a versatile and effective insulation solution. This article aims to explore the numerous advantages of vertical wire rock wool composite boards, shedding light on why they are becoming increasingly popular in modern construction and industrial applications.

II. Composition and Manufacturing Process

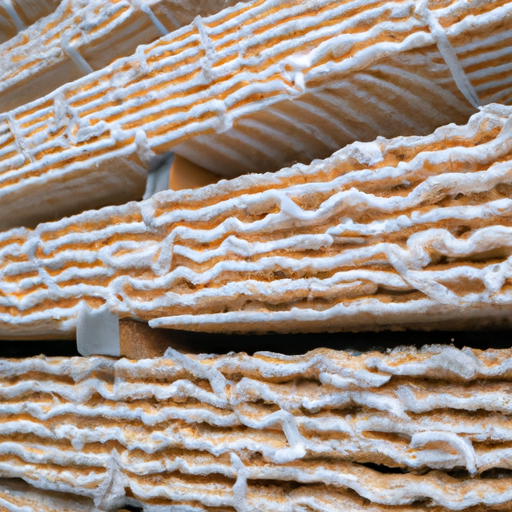

A. Description of Rock Wool and Its Properties

Rock wool, also known as mineral wool, is a fibrous material made from natural rock or stone. It is created by melting the raw materials at high temperatures and then spinning them into fibers. The resulting product boasts excellent thermal and acoustic insulation properties, making it a preferred choice for various applications. Rock wool is also non-combustible, providing an added layer of safety in construction.

B. Explanation of the Vertical Wire Reinforcement

The vertical wire reinforcement in these composite boards enhances their structural integrity. By incorporating vertical wires, manufacturers can improve the board's strength and resistance to deformation, ensuring that it maintains its shape and performance over time. This reinforcement is particularly beneficial in applications where the boards may be subjected to mechanical stress or impact.

C. Overview of the Composite Board Manufacturing Process

The manufacturing process of vertical wire rock wool composite boards involves several key steps. First, the rock wool is produced and then combined with vertical wire reinforcements. The mixture is then compressed and formed into boards, which are cured to achieve the desired properties. Quality control is paramount throughout this process to ensure that the final product meets industry standards and customer expectations.

D. Importance of Quality Control in Production

Quality control is essential in the production of vertical wire rock wool composite boards. Rigorous testing and inspection processes help to identify any defects or inconsistencies in the material, ensuring that only the highest quality products reach the market. This commitment to quality not only enhances the performance of the boards but also builds trust with customers.

III. Key Advantages of Vertical Wire Rock Wool Composite Boards

A. Superior Insulation Properties

1. Thermal Insulation Benefits

One of the standout features of vertical wire rock wool composite boards is their exceptional thermal insulation capabilities. These boards effectively reduce heat transfer, helping to maintain comfortable indoor temperatures and reduce energy consumption. This is particularly beneficial in both residential and commercial buildings, where energy efficiency is a top priority.

2. Acoustic Insulation Capabilities

In addition to thermal insulation, these boards also provide excellent acoustic insulation. The fibrous structure of rock wool absorbs sound waves, making it an ideal choice for applications where noise reduction is essential, such as in studios, auditoriums, and public spaces.

B. Fire Resistance

1. Non-Combustible Nature of Rock Wool

Rock wool is inherently non-combustible, meaning it does not ignite or contribute to the spread of fire. This property is crucial in construction, where fire safety is a significant concern. Vertical wire rock wool composite boards can help to enhance the overall fire resistance of a building, providing peace of mind to occupants and property owners.

2. Compliance with Fire Safety Regulations

Many building codes and regulations require specific fire safety standards to be met. Vertical wire rock wool composite boards comply with these regulations, making them a reliable choice for architects and builders looking to ensure safety in their projects.

C. Durability and Longevity

1. Resistance to Moisture and Mold

Vertical wire rock wool composite boards are resistant to moisture, which helps to prevent the growth of mold and mildew. This is particularly important in humid environments or areas prone to water exposure. The durability of these boards ensures that they maintain their performance over time, reducing the need for frequent replacements.

2. Structural Integrity Over Time

The combination of rock wool and vertical wire reinforcement contributes to the overall structural integrity of the boards. They are designed to withstand various environmental conditions, ensuring that they remain effective and reliable throughout their lifespan.

D. Lightweight and Easy to Handle

1. Benefits for Transportation and Installation

Despite their strength and durability, vertical wire rock wool composite boards are lightweight, making them easy to transport and handle during installation. This characteristic can significantly reduce transportation costs and labor time, making them an attractive option for contractors and builders.

2. Reduced Labor Costs

The ease of handling these boards can lead to reduced labor costs on construction sites. Workers can install them more quickly and efficiently, allowing projects to stay on schedule and within budget.

E. Environmental Benefits

1. Sustainable Sourcing of Raw Materials

Many manufacturers of vertical wire rock wool composite boards prioritize sustainability in their sourcing of raw materials. Rock wool is often made from abundant natural resources, and the production process can be designed to minimize environmental impact.

2. Recyclability and Reduced Environmental Impact

Vertical wire rock wool composite boards are recyclable, which helps to reduce waste in landfills. By choosing these boards, builders and property owners can contribute to a more sustainable construction industry.

IV. Applications of Vertical Wire Rock Wool Composite Boards

A. Construction and Building Insulation

1. Residential Buildings

Vertical wire rock wool composite boards are widely used in residential construction for insulation purposes. They help to create energy-efficient homes that are comfortable year-round.

2. Commercial Properties

In commercial properties, these boards provide effective insulation and fire resistance, making them suitable for a variety of applications, from office buildings to retail spaces.

B. Industrial Applications

1. Manufacturing Facilities

Manufacturing facilities often require robust insulation solutions to maintain temperature control and reduce noise levels. Vertical wire rock wool composite boards meet these needs effectively.

2. Power Plants and Refineries

In power plants and refineries, where fire safety and thermal insulation are critical, these composite boards provide reliable performance and compliance with safety regulations.

C. Acoustic Applications

1. Studios and Auditoriums

The acoustic insulation capabilities of vertical wire rock wool composite boards make them ideal for use in studios and auditoriums, where sound quality is paramount.

2. Public Spaces and Transportation Hubs

In public spaces and transportation hubs, these boards can help to manage noise levels, creating a more pleasant environment for occupants and visitors.

V. Comparison with Other Insulation Materials

A. Rock Wool vs. Fiberglass

1. Performance Differences

While both rock wool and fiberglass offer insulation benefits, rock wool has superior fire resistance and acoustic properties. This makes it a more versatile choice for various applications.

2. Cost Considerations

Although fiberglass insulation may be less expensive upfront, the long-term benefits of rock wool, including durability and energy efficiency, can make it a more cost-effective option over time.

B. Rock Wool vs. Foam Insulation

1. Environmental Impact

Rock wool is often considered more environmentally friendly than foam insulation, as it is made from natural materials and is recyclable. Foam insulation, on the other hand, can have a higher environmental impact due to its chemical composition.

2. Fire Safety Features

Rock wool's non-combustible nature gives it a significant advantage over foam insulation, which can be flammable. This makes rock wool a safer choice for many applications.

VI. Market Trends and Demand

A. Analysis of Current Market Trends

The demand for vertical wire rock wool composite boards is on the rise, driven by increasing awareness of energy efficiency and fire safety in construction. As more builders and property owners seek sustainable and effective insulation solutions, these boards are becoming a preferred choice.

B. Factors Driving the Demand for Vertical Wire Rock Wool Composite Boards

Several factors contribute to the growing demand for these products, including stricter building codes, a focus on sustainability, and the need for improved energy efficiency in both residential and commercial buildings.

C. Future Outlook for the Industry

As the construction industry continues to evolve, the future looks bright for vertical wire rock wool composite boards. With ongoing advancements in manufacturing processes and a growing emphasis on sustainability, these products are likely to remain in high demand.

VII. Conclusion

In summary, vertical wire rock wool composite boards offer a multitude of advantages that make them a compelling choice for insulation in various applications. From their superior thermal and acoustic insulation properties to their fire resistance and environmental benefits, these boards are well-suited to meet the demands of modern construction. As the industry continues to prioritize energy efficiency and safety, the popularity of vertical wire rock wool composite boards is expected to grow. For builders, architects, and property owners, exploring the potential of these innovative products can lead to more sustainable and effective insulation solutions.

VIII. References

- [Rock Wool Insulation: Benefits and Applications](https://www.example.com)

- [Fire Safety Regulations in Construction](https://www.example.com)

- [Sustainable Building Materials: A Comprehensive Guide](https://www.example.com)

- [Comparative Analysis of Insulation Materials](https://www.example.com)

This blog post provides a comprehensive overview of the advantages of vertical wire rock wool composite boards, highlighting their benefits, applications, and market trends. By understanding these factors, readers can make informed decisions about insulation materials for their projects.