Wirewound Resistor Product Training Precautions

I. Introduction

Wirewound resistors are essential components in various electronic applications, known for their precision and reliability. These resistors are constructed by winding a metal wire around a core, which allows them to handle higher power levels and provide stable resistance values. Given their importance in electronic circuits, proper training on wirewound resistors is crucial for engineers, technicians, and anyone involved in their application or maintenance. This blog post will explore the key precautions necessary for handling, installing, and maintaining wirewound resistors, ensuring safety and optimal performance.

II. Understanding Wirewound Resistors

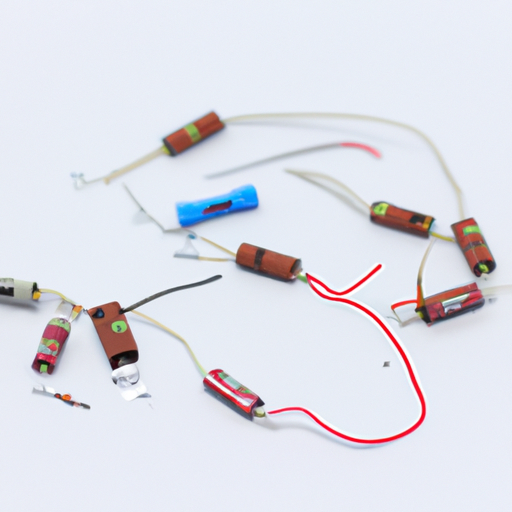

A. Construction and Materials

Wirewound resistors are made from a variety of materials, each chosen for specific properties. The wire types commonly used include:

1. **Nickel-Chromium**: Known for its high-temperature stability and resistance to oxidation, making it suitable for high-power applications.

2. **Copper-Nickel**: Offers good conductivity and is often used in lower power applications.

The core materials, such as ceramic and glass, provide structural integrity and thermal stability, allowing the resistor to function effectively under varying conditions.

B. Working Principle

The working principle of wirewound resistors is based on Ohm's Law, where the resistance is determined by the material's resistivity, the length of the wire, and its cross-sectional area. When an electric current passes through the wire, it generates heat due to resistance, which is dissipated into the surrounding environment.

C. Applications and Use Cases

Wirewound resistors are utilized in a wide range of applications, including:

1. **Power Electronics**: They are often used in power supplies and amplifiers due to their ability to handle high power levels.

2. **Audio Equipment**: In audio circuits, wirewound resistors provide accurate resistance values, ensuring high-quality sound reproduction.

3. **Measurement Devices**: These resistors are critical in precision measurement instruments, where accuracy is paramount.

III. Safety Precautions

A. General Safety Guidelines

Safety is paramount when working with wirewound resistors. Here are some general safety guidelines:

1. **Personal Protective Equipment (PPE)**: Always wear appropriate PPE, including safety glasses and gloves, to protect against potential hazards.

2. **Electrical Safety**: Ensure that all equipment is de-energized before handling to prevent electrical shock.

B. Handling and Storage

Proper handling and storage of wirewound resistors are essential to maintain their integrity:

1. **Proper Handling Techniques**: Avoid dropping or applying excessive force to resistors, as this can cause mechanical damage.

2. **Storage Conditions**: Store resistors in a cool, dry place, away from direct sunlight and moisture, to prevent degradation.

C. Disposal Considerations

When disposing of wirewound resistors, consider the following:

1. **Environmental Impact**: Many resistors contain materials that can be harmful to the environment. Follow local regulations for disposal.

2. **Regulatory Compliance**: Ensure compliance with relevant regulations regarding electronic waste disposal.

IV. Installation Precautions

A. Soldering Techniques

Proper soldering techniques are crucial for the effective installation of wirewound resistors:

1. **Temperature Control**: Use a soldering iron with adjustable temperature settings to prevent overheating the resistor, which can alter its resistance.

2. **Solder Types and Compatibility**: Choose solder that is compatible with the resistor materials to ensure a strong connection.

B. Circuit Design Considerations

When designing circuits that include wirewound resistors, keep these factors in mind:

1. **Resistance Values and Tolerances**: Select resistors with appropriate resistance values and tolerances to meet circuit requirements.

2. **Power Ratings and Heat Dissipation**: Ensure that the resistor's power rating is sufficient for the application to prevent overheating.

C. Testing and Verification

After installation, testing is essential to verify proper functionality:

1. **Multimeter Usage**: Use a multimeter to check the resistance value and ensure it matches the specified value.

2. **Load Testing Procedures**: Conduct load tests to confirm that the resistor can handle the expected power levels without overheating.

V. Operational Precautions

A. Monitoring Performance

Regular monitoring of wirewound resistors is vital for maintaining performance:

1. **Temperature Monitoring**: Keep an eye on the operating temperature to prevent overheating, which can lead to failure.

2. **Resistance Drift**: Monitor for any changes in resistance over time, as this can indicate potential issues.

B. Identifying Signs of Failure

Being able to identify signs of failure early can prevent further damage:

1. **Visual Inspection**: Regularly inspect resistors for signs of discoloration, cracking, or other physical damage.

2. **Electrical Testing**: Perform electrical tests to check for abnormal resistance values or other indicators of failure.

C. Maintenance Practices

Implementing regular maintenance practices can extend the life of wirewound resistors:

1. **Regular Checks**: Schedule routine inspections to catch potential issues before they escalate.

2. **Cleaning Procedures**: Keep resistors clean and free from dust and debris, which can affect performance.

VI. Troubleshooting Common Issues

A. Overheating

Overheating is a common issue with wirewound resistors. Causes may include:

1. **Inadequate Power Rating**: Ensure that the resistor's power rating matches the application requirements.

2. **Poor Heat Dissipation**: Improve airflow around the resistor to enhance heat dissipation.

B. Resistance Changes

Resistance changes can occur due to various factors:

1. **Temperature Effects**: Be aware that resistance can change with temperature; use resistors with low temperature coefficients for critical applications.

2. **Mechanical Stress**: Avoid applying mechanical stress to resistors, as this can alter their resistance.

C. Mechanical Damage

Mechanical damage can compromise resistor performance:

1. **Prevention**: Use protective enclosures to shield resistors from physical damage.

2. **Repair**: If damage occurs, replace the resistor rather than attempting repairs, as this can lead to unreliable performance.

VII. Training and Education

A. Importance of Continuous Learning

The field of electronics is constantly evolving, making continuous learning essential for professionals working with wirewound resistors.

B. Recommended Training Programs

Consider enrolling in training programs that focus on electronic components, circuit design, and safety practices to enhance your knowledge and skills.

C. Resources for Further Education

Utilize online resources, webinars, and industry publications to stay updated on the latest advancements and best practices in the field.

VIII. Conclusion

In summary, wirewound resistors are critical components in many electronic applications, and understanding the precautions necessary for their handling, installation, and maintenance is essential for ensuring safety and performance. By adhering to the guidelines outlined in this post, professionals can minimize risks and enhance the reliability of their electronic systems. Ongoing education and awareness are vital in this ever-evolving field, encouraging a culture of safety and excellence.

IX. References

1. Industry Standards and Guidelines: Refer to organizations such as the Institute of Electrical and Electronics Engineers (IEEE) for standards related to electronic components.

2. Recommended Reading Materials: Books and articles on electronic components and circuit design can provide deeper insights.

3. Online Resources and Courses: Websites like Coursera, edX, and industry-specific training platforms offer valuable courses on electronics and safety practices.

By following these guidelines and continuously seeking knowledge, professionals can ensure the effective use of wirewound resistors in their applications, contributing to the overall success of their projects.